|

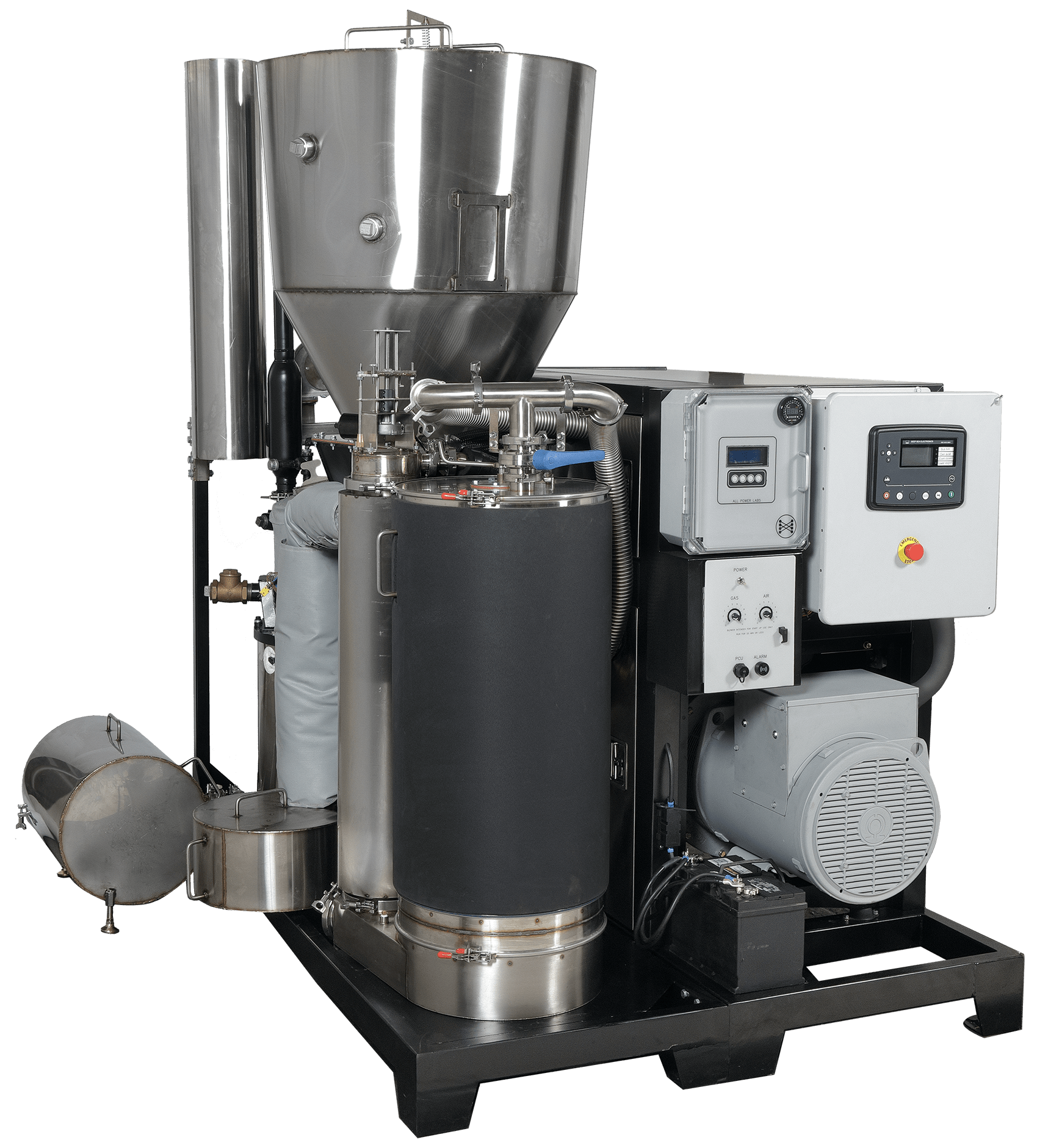

The New Updated PP30 Power Pallet

The PP30 is the latest generation of the Power Pallet biomass gasifier genset system. It represents the largest upgrade of the capabilities and convenience of the Power Pallet up to this point. The PP30 features:

- Larger, more efficient engine and more efficient generator, which increases the power output to 25kW, vs. the 18kW of the PP20.

- Standard feature CHP water heating capability, utilizing three stages of waste heat recovery to produce up to 2kW of thermal output per 1kW of electrical load

- Standard feature grid-tie hardware, enabling all PP30s to integrate into a microgrid with existing power sources or the main grid.

- Simplified filtration architecture which eliminates the need to sift and prepare charcoal filter media while also eliminating the regular maintenance task of purging the engine.

- Stainless-steel enclosure and a selectively activated electric cooling fan system to reduce noise.

- Conical jam-resistant hopper to reduce risk of feedstock jams.

- Larger ash collector vessel and cyclone dust can.

- New high efficiency genheads configurable to three phase, at 190-240 / 380-480 V Phase-Phase, 60 Hz or 50 Hz.

Please review the PP30 Basic Considerations to qualify your use case.

PP30 Operation Manual is available on the Support Page.

Note that the Technician’s Handbook available there is based on the PP20, and is currently being updated to include PP30 specifics, although many features are unchanged or similar.

Why it’s different

See PP30 vs PP20 Comparison Sheet Here

The PP30 Power Pallet is the culmination of our long work to create an expertly engineered, small-scale gasification solution that is realistic for today’s user. While personal scale gasification has long held tremendous promise, the realities of making it work usually prove too much for regular mortals. The high bar of operator expertise and extreme sensitivity to fuel particulars usually combine to make what seems simple in principle, exceedingly difficult in practice.

The Power Pallet has significantly widened this window for success by embedding the needed operator expertise in an onboard electronic brain. These smarts are further extended by a multi-stage gasification architecture and an innovative waste heat capture and recycling system – what we call the Tower of Total Thermal Integration (TOTTI). In traditional systems, hot engine exhaust and hot output wood gas have been problems requiring extra space and cooling components to counter. With the GEK TOTTI, we’ve transformed this waste energy into useful new inputs to the gasification process. It’s like adding a new free heat source to fix the old and well known thermal challenges of a gasifier.

This Gasifier-Engine thermal integration significantly improves tar conversion, fuel flexibility and general efficiency of the gasifier-engine system. It enables the Power Pallet to solve the tar issue in the reactor, rather than in a large downstream filtering system, significantly reducing the cost, complexity and installation footprint in the process.

Engine and Genhead

The PP30 uses an advanced 4.0 liter 4 cylinder Ashok Leyland engine, spark-fired, but based on their heavy-duty diesel industrial engine.

The engine is mated to a Marathon genhead with automatic voltage frequency and 3x rated amperage at surge for high machinery start capacity. The genhead is 12 wire so they can be configured to single, split or three phase, in wye or delta configuration and supports all common global voltages: 120, 208, 240 and 400V AC, at either 50 hz or 60 hz.

Actual power produced is highly dependent on the fuel shape, size and moisture content. Solid biomass is not the consistent fuel source like we assume with diesel or gasoline. We have used “25 kW” rating although maximum power at 60 Hz is actually somewhat higher.

Support

ALL Power Labs provides extensive customer support before and after a sale, online and in person, to help you get your project up and running. This includes:

- The Power Pallet product documentation

- Pre-sales consulting available by contacting us through our contact page

- On-site commissioning and training for a nominal fee

FAQ

Frequently Asked Questions. Click to view answer:

Rated continuous electrical power for the PP30 is 25 kW at 60 Hz and 22 kW at 50 Hz when grid tied and 22 kW and 18 kW off grid. With the standard 2-stage heat exchanger, it produces an additional 1.5 kW thermal for each kW electrical, with the optional 3 stage, 2 kWt/kWe

The rate of consumption is not constant; it depends on the electrical load. The quick rule of thumb for PP30 biomass consumption is 1 kg of dry feedstock will produce 1 kWh of electricity. This ratio adjusts with the moisture level. For example, a 20% moisture feedstock will have a conversion ratio of 1.2 kg/kWh.

20 pounds (lbs) of biomass will produce about as much electricity as 1 gallon of gasoline or diesel. So, 1 tonne of biomass through a gasifier-engine system generates about the same amount of electrical power as 100 gal of liquid fuel, or 1 MWh of electricity. 1 kg of biomass ~ 2lbs biomass ~ 2m3/h woodgas ~ 1HP for an hour ~ 1kWh. However, the additional thermal energy available from the gasifier allows our Combined Heat and Power (CHP) system produce much more heat than a fossil fuel generator equipped with a CHP could.

The Power Pallet is designed to gasify woody biomass feedstocks. Wood chips and walnut shells are what we use during our product development but other nut shells, such as palm kernel, macadamia, and hazelnut have also been used successfully by our customers. Other feedstocks, such as corn cobs have been tested and can work, however with additional maintenance and more frequent feedstock jams. Other untested feedstocks might be compatible, or able to be processed to become compatible, but their use without APL testing and approval will void our warranty. More details are available on our website and in our manual.

These are the important general characteristics:

Particle Size: Chunks should be between 1-4cm (0.5 to 1.5 inches) in size. It is particularly important to keep out the really fine particles, since these tend to clog the reactor and prevent the production of gas. Large pieces can jam the feed mechanisms.

Moisture: The feedstock should have a maximum moisture content of 30%, 15%-20% is ideal, with a minimum of 5%

Disqualifiers: If the feedstock has any plastics or rubber in it (such as municipal solid waste, waste tires) must not be used because these materials soften and melt and stick together, and are not chemically compatible with our process.

Ash content: The feedstock should have minimal silica ash, and over-all ash should be comparable to wood. Materials with high silica ash, such as rice hulls, almond husks, palm fronds and other palm waste, are not suitable because the silica will fuse into clinkers in the reactor which can damage the reactor and block gas flow.

These fuels are completely incompatible:

- Municipal Solid Waste / Trash

- Coal

- Plastics

- Manure – Cow, Pig, Chicken, etc

- Tires

Spiral-bladed-auger chippers, such as those made by Laimet, are more expensive than bladed-flywheel chippers, but they produce very consistent chips, nearly all of which are the correct size, resulting in the elimination of sifting, less waste and lower operating costs. Laimet’s PS-10 model is the correct scale for supporting the PP30, but requires a power take-off (PTO), such as from a truck or a tractor, to drive the chipper. Disc and drum chippers are more common and less expensive, but produce various sized chips, and so must be sifted to obtain chips in the right size range. This is the least expensive set-up, but will result in greater waste (the proportion of feedstock that is the wrong size) and increased labor and therefore higher operating costs to perform the sifting. We recommend chipping and sorting/sifting the wood before drying it. Dry wood tends to form splinters which can cause feed problems. Chipped wood also dries faster due to the increased surface area exposed to the air.

Yes, as long as they are all approved feedstocks or you have run testing with our technicians to assure that a novel feedstock is compatible.

We like to say there is a “Triangle of Dependencies” for successful gasification: the operator, the fuel, and the machine. The weakest link in this triangle is usually the operator. We offer technical publications, online courses, and Youtube videos to supply the needed know how. We also will provide in-person training during our on-site commissioning process.

Power Pallets are built to customer specifications (kW capacity, phase, Hz, Voltage, etc ) and shipping time can vary. Please verify production time when placing an order and ask about the expedite fee if you are needing to meet a deadline. In normal circumstances PP30 Power Pallets usually ship 90 days after payment is received.

Shipping costs will vary widely depending on your site location and whether you select air or surface shipping. Surface shipping will be lower costs with a longer delivery time. Contact us for estimated shipping costs or use sizes and weights below to have an estimate made by your preferred courier service.

| PP30 | 67” x 56” x 54” | 170 x 142 x 137 cm | 1406 kg | 8502.20.0080 |

| PP30 Hopper | 33″ x 33″ x 45″ | 84 x 84 x 114 cm | 91 kg | 7326.90.8588 |

The PP30 Power Pallet has a minimum load requirement of 3 kW. Ideally, the electrical load should be kept above 5 kW. If you draw less than the minimum electrical load the engine does not provide enough suction to allow the reactor to run hot enough to produce clean gas which will foul the system much more quickly, especially the filter.

No. The Power Pallet is intended to operate in daily sessions followed by required daily maintenance procedures. These involve at least emptying the ash-collection vessel and the cyclone dust can. Sessions can vary from 8-16 hours depending on the electrical load and feedstock chip quality. In order to prevent damage to the machine, if either the ash collection vessel or the cyclone dust can are filled to capacity, the machine must be shut-down and these must be emptied before it can run further.

No. Compressing and storing producer gas is too dangerous and would not be cost effective because it has very low energy density. Power Pallets are not able to output gas without the engine’s suction and heat, which are essential features of its operation.

It will depend on the specifics of your use case. The PP30 features a stainless steel 88-gallon hopper, which usually lasts from 6-10 hours. However, if using a low-density feedstock and running at maximum power output (25 kW), the hopper may be emptied in as little as 2 hours. The exact runtime will depend on your load and the density and moisture content of your feedstock. You can estimate the impact of the moisture by increasing the standard consumption of 1 kg of dry (0% moisture) feedstock per 1 kWh based on the moisture content of your feedstock. For example, a 10% moisture feedstock would change the conversion rate to 1.1 kg of feedstock per 1 kWh, 20% to 1.2 kg/kWh, and 30% to 1.3 kg/kWh.

The following are the most common maintenance tasks that must be performed on a Power Pallet to keep it running smoothly:

- Refill the hopper when the feedstock runs low. (This is for those who are manually refilling the hopper, not for users of the continuous feed hopper lid.) This must be done quickly when machine is running (1-3 minutes) because the hopper must remain sealed to maintain the vacuum pressure which powers the suction of gases through the machine. This may happen several times per run session if you are powering a high load.

- Empty the ash collection vessel (ACV). The ACV needs to be emptied daily. The Power Pallet cannot be running while emptying the ash due to the intense heat coming from the reactor and the potential for mixing oxygen with hot, flammable gases. Therefore the Power Pallet must be permitted to cool down to a safe handling temperature before the ACV can be emptied. How often this must be done depends on the electrical load on the generator and the kind of feedstock you are using. At high loads, the ACV should be able to handle at least an 8 hour session. At more moderate loads, the ACV should be able to handle 16 hour sessions. Regardless of the load, the ACV should be emptied daily.

- Empty the cyclone dust can. This can, which collects charcoal dust that the cyclone separates out of the gas, needs to be emptied daily. This also requires the machine to be turned off and cooled down. We recommend emptying the cyclone jar when you empty the ash.

Optional Accessories:

Continuous Feed Airlock System

To eliminate manual refilling of the hopper, ALL Power Labs is now offering a Continuous Feed Airlock as an option on all Power Pallets. Controlled by an Electronic Control Unit (ECU) with an array of sensors, this system allows a store of feedstock at ground level to be automatically fed, via a standard agricultural feed transport (not included), into the hopper through an automated gate valve on the hopper lid. The horizontal motion of the linear drive operating the gate valve is converted into a vertical sealing force by an innovative leaf spring system, ensuring an airtight seal and reliable operation.Included in the systems are the automated gate valve assembly, the custom ECU, upper and lower level sensors and wiring harness.

Using an open-source processor with an APL-designed circuit board, the ECU reads data from the sensors installed in the hopper and opens the gate valve when the feedstock is low, then signals the motorized feed transport to reload the hopper. Once it detects the hopper is full, the ECU shuts off the feed transport (not included) then closes the gate valve. This smart automation also reads gate position and motor-current sensors to assure safe operation for both operators and the Power Pallet. If problems are detected, the ECU will set the Continuous Feed system into various safe and stable modes and trigger alarms to alert the operator.