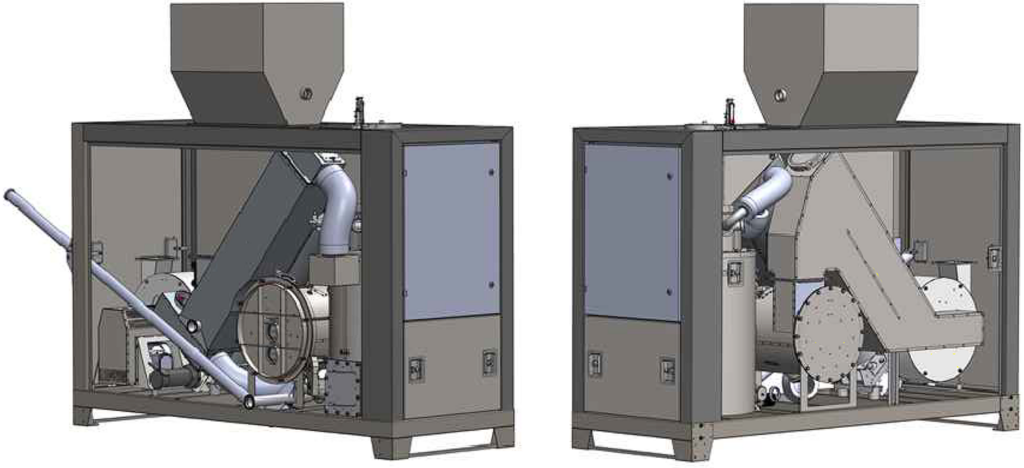

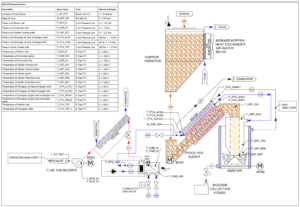

ALL Power Lab’s CharPallet R&D (CP R&D) unit is based on our third-generation reactor architecture incorporating APL’s major breakthroughs in gasifier architecture and controls systems to widen the range of acceptable feedstocks and optimize the gasification process.

CP R&D is specifically designed as a laboratory test platform to support research in the areas of biomass gasification, biochar, activated carbon, biomaterials and carbon material development. The unit incorporates up to 30 temperature, pressure, gas and emissions sensing points coupled with our latest developments in controls and software architecture for ease of data collection, management and analysis.

Improved Gasification Process:

Excellent Carbon and Gas Outputs – Extensive testing and process refinement for more than a decade results in high-quality product outputs:

Smart Technology – Smarter than any previous APL products, the CharPallet R&D uses Internet of Things (IoT) protocols and systems that include:

Modular Design – The v3.0 biomass gasification system is configurable to support the following use cases:

We are planning for pre-sales of the CharPallet to support limited production release in early 2026 with target base price well below our Power Pallet.

We will be able to meet this target by getting a minimum number of reservations to enable negotiations with our suppliers. Reservation fee is $300 per unit and adds you to the production queue.

Click for CharPallet reservation here.

Please fill out this Contact Form along with details of your use case so we can respond appropriately.

The CharPallet R&D unit will be available to a limited number of customers starting in mid 2026.

The CharPallet R&D unit will be priced at USD 85k for the basic system. Optional modules to enable additional functionality such as gas and emissions testing will be an additional charge. Final prices provided on a formal quote.

The CharPallet R&D unit is an excellent tool for academic institutions working in R&D or education in the biochar and renewable energy spaces.

Please review this Appropriate Feedstock link. However, ongoing testing and refinement of our novel tar-cracking Swirl Hearth reactor architecture indicates greatly expanded compatibility with a wider range of feedstocks. We’ve had recent success with wood chips, walnut and pistachio shells, and wood pellets.

The quality of the biochar produced is highly electrically conductive with extremely low tar/PAH content. Please review these Skycarbon Specifications which show biochar qualities and certifications for walnut feedstock. We have been recording similar results with other feedstocks.

Measurements of combustion emissions of the R&D unit have shown NOx at below 200 ppm and CO below 30 ppm at 15% O2. The optional emissions package allows for monitoring of these emissions.

Unlike the Power Pallet, the CharPallet does not integrate an engine and generator. The CharPallet is planned to be a Combined Heat and Biochar (CHAB) production reactor with a biochar output of 5 kg/hr compared to the PP30’s 2 kg/hr. It can be configured to provide 50 kWth heat output, similar to the PP30 but consuming 2 kW of electrical power rather than any electrical output. It is roughly half the footprint and price, and one third the weight of the PP30.

Yes. The optional gas conditioning module is recommended which provides valving and other components to safely off-take gas produced by the system.

Yes. APL has extensive experience and expertise in gasifier design and operations, particularly in control and monitoring systems. We offer comprehensive system design and engineering support at reasonable consultation rates.

A: The CharPallet can be observed in operation at Berkeley CA or Modena Italy. Please reach out to schedule an appointment.