If you are interested in producing your own biochar, check out our Products page to review our various systems and their biochar output. Our newest product, the Chartainer, capable of processing 250kg biomass per hour into 40kg of high-quality, high-temperature SkyCarbon biochar, is nearing beta distribution. Contact sales@allpowerlabs.com for more information or to get into the queue for our early releases.

We currently produce large quantities of SkyCarbon biochar at our Berkeley CA facility and have it available for retail sale through our Local Carbon Network community drawdown project. Requests for larger bulk purchases should also be sent to sales@allpowerlabs.com.

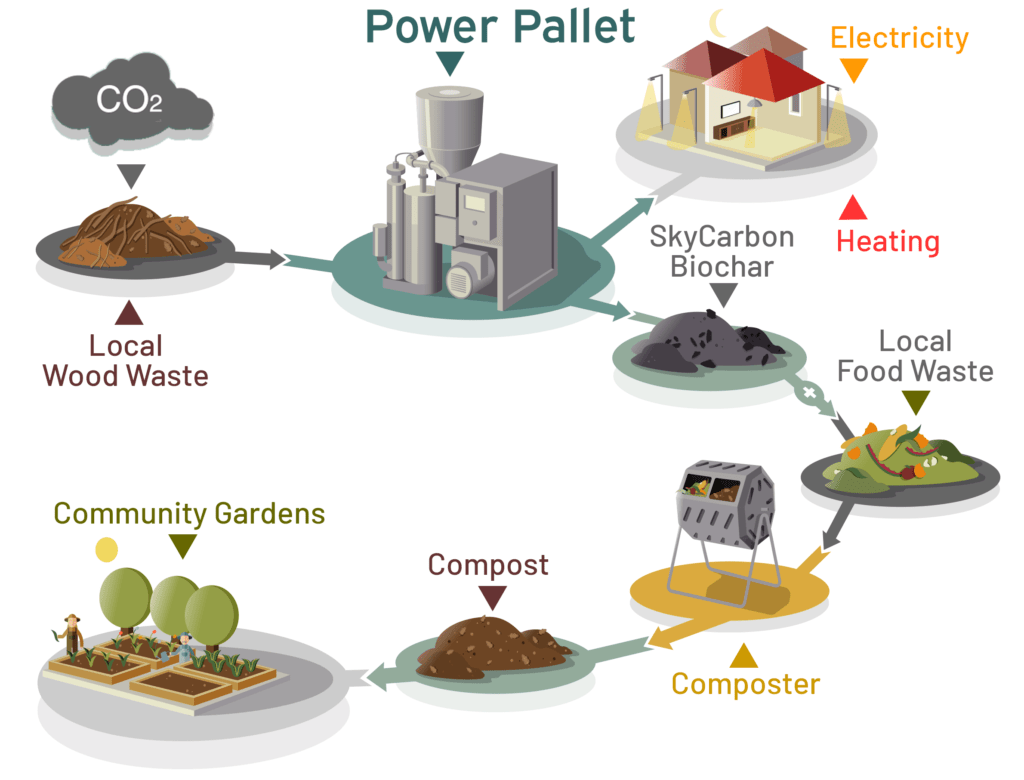

Adding biochar to soil can result in a significant and long-term sink of atmospheric CO2, especially when co-composted with other green waste which creates a large multiplier effect.

Agricultural-sector emissions were a key topic in the COP27 meeting held in Egypt, identifying biochar as a uniquely comprehensive solution. Nitrogen losses to the atmosphere, phosphorus losses to water tables, and the bioavailability of soil contaminants are all particularly well addressed by biochar soil amendment. These are in addition to the already well documented soil-health benefits of biochar in water and nutrient retention, reduction of methane emissions, and support of the soil microbiome.

Biochar production and use are widely seen as a vital component of global climate-change mitigation efforts and biochar markets and credits are an increasingly common and important tool in this effort. APL has increased its focus on the science and technology of biochar, working with agronomists and academics, the California Energy Commission, and US Departments of Energy and Agriculture to continue to explore the cutting edge of the practical and effective production and use of biochar. To this end, we have continued to develop and improve our technology to optimize biochar production in our existing products like the Power Pallet and PowerTainer, as well as with the design of new products, such as the CharTainer and the creation of various community-based programs to help achieve these goals.

All of APL’s machines output biochar generated by the pyrolysis of their waste biomass feedstocks, which come almost exclusively from agricultural and forestry residues. Our SkyCarbon biochar’s testing confirms that it meets the rigorous standards for is certification by the International Biochar Initiative (IBI). Since its inception, IBI has established itself as the leading non-profit dedicated to the promotion of biochar research and commercialization. We are grateful for their efforts and proud to have been able to meet their standards, confident that this will assist in our efforts to commercialize and expand the positive climate impact of APL technology.

Biochar can be generated by pyrolysis at any temperature above about 350°C , but at those lower temperatures, various contaminants, tars, and harmful combustion byproducts such as Polycyclic Aromatic Hydrocarbons (PAHs) are usually measured at undesirably high levels. Temperatures in APL’s gasifiers, in excess of 650°C, assure more complete conversion of these chemicals into a stable carbon matrix. Skycarbon’s increased surface area, electrical and microbiological activity, and low levels of contaminants results in a particularly high quality biochar.

Biochar is poised to transform agriculture

Chemical fertilizers were one key to the huge increases in agricultural productivity created by the green revolution in the 60’s. However, serious unintended ecological, economic, and climate consequences threaten to derail the huge crop yield increases that have helped reduce global poverty and starvation. Developing systems and techniques to make these industrial agricultural practices more sustainable is vital to solving the climate puzzle. Increasing evidence is validating co-composted biochar as a promising technique to maintain agricultural productivity while simultaneously reducing atmospheric GHGs.

As the climate continues to change, with its shifts and uncertainties in rainfall and increasingly severe droughts, more resilient agricultural systems are going to be essential. Biochar’s most well documented and robust ability is its ability to retain more water in the soil for longer periods. This alone makes biochar an increasingly desirable commodity as a soil amendment.

Subsidies for carbon capture solutions

These agronomic benefits make biochar a particularly good candidate for carbon credits and other carbon capture programs. Hopefully these incentives aimed at climate changes mitigation will hasten the adoption of restorative agricultural practices, for which biochar is becoming an increasingly active component.

Our CharTainer containerized biochar pyrolysis system, which is nearing commercial release with the generous support of the California Energy Commission, maximizes biomass throughput and minimizes levels of harmful fractions in the SkyCarbon biochar it creates. California has some of the most productive farmland on earth, often called the salad bowl of the world. There is a golden opportunity here in California to commercialize the integration of the desperately needed forest fire remediation in the Sierra Nevada, with drawing down atmospheric CO2 at the same time that it revitalizes the health of our soil.

All Power Labs, as usual, is committed to creating game-changing devices and processes at the forefront of climate mitigation technology.

SkyCarbon Specifications

Source and composition

| BIOCHAR COUNTRY OF ORIGIN | United States |

| FEEDSTOCK COUNTRY OF ORIGIN | United States |

| FEEDSTOCK TYPE | Unprocessed Feedstock |

| FEEDSTOCK COMPOSITION DECLARATION | Walnut Shell – 100% |

| Moisture (at time of analysis) | 13% |

| Organic Carbon (Corg) | 67.8% |

| H:Corg | 0.44 |

| Total Ash | 15.4% |

| Total N | 0.46% |

| pH | 9.79 |

| Electrical Conductivity | 7.180 dS/m |

| Liming | 13.9% CaCO3 |

Particle size

| < 0.5 mm | 10.3% |

| 0.5 – 1 mm | 8.7% |

| 1 – 2 mm | 18.5% |

| 2 – 4 mm | 34.4% |

| 4 – 8 mm | 25.2% |

| 8 – 16 mm | 3.0% |

Laboratory analysis results

| Germination Inhibition Assay | PASS |

| Polycyclic Aromatic Hydrocarbons (PAHs), total (sum of 16 US EPA PAHs) | 67.46 mg/kg – PASS |

| Polycyclic Aromatic Hydrocarbons (PAHs), B(a)P-TEEQ basis | 0 mg/kg – PASS |

| Dioxin/Furan (PCDD/Fs), WHO-TEQ basis | 0 mg/kg – PASS |

| Polychlorinated Biphenyls (PCBs), total (sum of 7 US EPA PCBs) | 0 mg/kg – PASS |

| Arsenic | 0.6 mg/kg – PASS |

| Cadmium | ND – PASS |

| Chromium | 1.4 mg/kg – PASS |

| Cobalt | ND – PASS |

| Copper | 46.3 mg/kg – PASS |

| Lead | 0.3 mg/kg – PASS |

| Mercury | ND – PASS |

| Molybdenum | ND – PASS |

| Nickel | 1.6 mg/kg – PASS |

| Selenium | ND – PASS |

| Zinc | 4.1 mg/kg – PASS |

| Boron | 89.6 mg/kg – DECLARATION |

| Chlorine | 5341 mg/kg – DECLARATION |

| Sodium | ND – DECLARATION |

| Iron | 341 mg/kg – DECLARATION |

| Manganese | 41 mg/kg – DECLARATION |