Announcing the New v.5 GEK Gasifier & Power Pallet

Now with up to 24hr run time, increased reliability and ease of use Today we’re pleased to announce the new v5.0 GEK Gasifier and related Power Pallet. Two years in development, the v5.0 represents a generational change in our core gasifier technology, incorporating all we’ve learned over the last five years of development and deployment. For you, this means a significant advancement in performance, ease of use, and cost of operation/maintenance. All Power Pallets purchased from today forward will incorporate this new generation v5.0 gasifier and related auxiliary components. The original modular GEK architecture has been an extremely powerful……

Corncobs into power: a Uganda case study + new ROI calculator

Making energy From “waste”– a case study in corn from Uganda As part of Richard Scott’s recent African field trip, he stopped in to help Pamoja Cleantech set up their new Power Pallets in Kampala, Uganda. This project–as well as the previous one discussed in Liberia, and the one we’ll report on soon from Malawi– are all proof of concept projects for a larger roll out of rural electrification in Africa using biomass gasification. Pamoja Cleantech’s gasifiers (Pamoja means “together as one” in Swahili) are running on corn cobs, with the energy being used to power a corn flour mill……

Grid-tie for the 20kW Power Pallet

We’ve long wanted to provide a reasonably priced grid-tie solution for the Power Pallet. However sync equipment for small scale systems is scarce, and usually at price points near equal the Power Pallet itself. Today we’re announcing the availability of a fully complete, non-hacked, and equipment certified grid-tie solution for the 20kw Power Pallet for $4,995. This is a solution that will work for nearly all global grid standards, as well as enable off-grid parallel feeding with large gensets already at your facility. We think this tie solution is a game changer for the broad usability of the Power Pallet.……

APL in the Field: Indonesia Report

Yoav and I just returned from a trip to Indonesia to help with the set up and operational instruction for 2 Power Pallets there. They are being integrated into a pilot stage “Village Hub” project. This pilot is located next to a palm sugar factory run by the Masarang Foundation (http://www.masarang.nl/). The factory uses waste geothermal heat from a 35 MW geothermal plant to dry and prepare palm sugar. This sugar is prepared from the sap of the Arenga Palm (http://en.wikipedia.org/wiki/Arenga_pinnata), a species studied by Willie Smits who studied forestry in the Netherlands (and gave a great TED talk. The……

June 17-19 Workshop Projects and Schedule

Father’s Day Gasification and Biochar Workshop: June 17-19, 2011 Opening Intro & Lecture: Friday, June 17, 7:30 – 9:30PM Weekend Build, Run and Test: Saturday and Sunday, June 17-19, 11am – 7pm Location: ALL Power Labs, 1010 Murray Street, Berkeley CA 94710 Cost: Free if you are a GEK or BEK owner, either through self build or purchase. Otherwise, $100 for weekend. Our summer workshop is fast approaching- June 17th – 19th. Many of you have already RSVP’ed and are flying in from the 4 corners, but there is still room for more. So come join us for a quality……

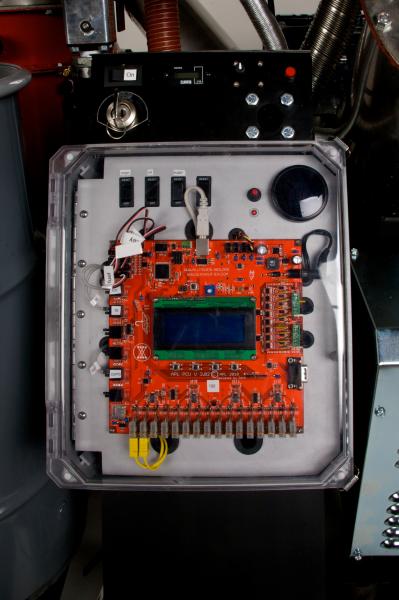

A Closer Look At The 2011 Power Pallet

The first edition of the 10kW GEK Power Pallet combined our Tower of Total Thermal Integration with a Kohler v-twin engine. In October of 2010 we began production of the second version, which used a Kubota 3-cylinder industrial spark-fired diesel designed specifically for use with a gaseous fuel, and a Meccalte genhead that could be configured to the requirements of the user’s energy network. This engine, when governed electronically, is stunningly smooth and quiet. Here is a feature-by-feature breakdown of the innovations that have been incorporated into the current Power Pallet line: Control Panel Mount The Process Control Unit and……

New Year Power Pallet Upgrades, GEK CHP, & Other Upgrades

Welcome to the New Year. Here’s what we’ve been up to for the last couple months, and some pointers to what’s coming in the months ahead. This winter we’ve been deep in Power Pallet refinement in response to user feedback and general product maturation. The upgrades fortunately no longer relate to the core gasifier, but rather to details in the larger Power Pallet control system and integrated product. The raw gasifier is what always gets the attention, but we’re finding that real usability is achieved (or not) across lots of details elsewhere. Once you get past the early demos and……

CHP on the Cheap

We’re working towards a native chp system built standard into the power pallet. the goal is to make available both the hot water from the engine cooling system, as well as the hot exhaust after the pyrocoil, towards off board heating needs. we’re working on liquid heat exchangers to produce hot water for heating and hot shower water. we’re also working on hot gas to gas exchangers so you can get hot air for fuel drying and ag crop drying. There are many fancy ways to do this. bear will document these later. there are also some cheap obtainium ways……

Fall Workshop, Oct 8-11: Power Pallet 7 day test run- Biochar Database – Syngas-to-Liquids

Gasification PowerExchange Workshop #9 Opening Intro/ Lecture: Friday, October 8, 7:30-9:30PM Weekend Build, Run and Test: Saturday, Sunday, and Monday, October 9-11, 11am – 7pm Location: ALL Power Labs, 1010 Murray Street. Berkeley, CA Contact: jim ^at^ allpowerlabs dot org Cost: Free if you are a GEK or BEK owner, either through self build or purchase. Otherwise, $100 for weekend. The quarterly workshop series at ALL Power Labs offers education, research reports and hands-on experience to bring more people to successful operation of small scale gasification and pyrolysis units. The event is open everyone, not just GEK or BEK users/owners. ……

Workshop report. Power Pallet 4 day / 30 hour run report

The workshop weekend was great fun and good learning as usual– and this time with a gasifier-genset running through the whole event. Thank you again to all who joined us, and for the many new friends that came out of the process. Longest distance award this time goes to Abau who flew in all the way from the Congo, and flew back with many plans for gasification in central Africa. The most interesting new contributors were Kyoung Ro with his talk on animal manure biochars and Devinder Mahajan for his survey of liquification pathways and related liquification technology. Mixing in……