From Workshop, to White House, to Silicon Valley

As those who’ve been involved in this for a long while know, one of the biggest challenges in gasification is simply getting people to know it exists. We keep chipping away at this invisibility–as you can see in the events below–and plan more chipping around the upcoming COP21 climate meetings in Paris in December. More on our plans to shout “gasification + biochar = carbon negative energy” in a very crowded room in Paris coming up shortly. In the interim, here’s what October looked like around APL. First: OEM Workshop First came our GEK Gasifier OEM workshop ten days ago.These gatherings……

Return of the GEK

GEK Gasifier, available again after two year hiatus All Power Labs began in 2008 by selling small scale gasifier kits for DIY enthusiasts and university researchers. Our intent was to provide a “LEGO kit” of gasification to spark new work and new conversation in the relatively uneventful field of biomass thermal conversion. Over the following years we were amazed at the interest these kits generated globally, and the acceleration of collaborative research and knowledge exchange that followed. Here’s what the GEK v1 looked like in 2008: We ultimately sold over 300 of these kits before they were eclipsed by our……

Gasification Workshop Weekend: March 30 – April 1, 2012 Berkeley, CA

Gasification PowerExchange Workshop #11: March 30 – April 1 2012 Gasifier Power System Showcase: 10kw, 20kw & 100kw, GEK building and running, More Lister spark conversion Gasification Lecture and Demo: Friday, March 30, 7:30-9:30PM Building, Running and and Testing: Saturday and Sunday, March 30 and April 1, 11am – 7pm Location: ALL Power Labs, 1010 Murray Street. Berkeley, CA Contact: sales ^at^ allpowerlabs.org Cost: Free for GEK owners. $100 otherwise Join us at ALL Power Labs in Berkeley CA, March 30 – April 1 for the next in our long running series of Biomass Gasification workshop weekends. It has been way too……

GEK v4.2 Gasifier Fabrication Guide – Build Your Own!

Welcome back after a quiet late summer sans Geknews posts. Sadly, quiet on this end didn’t relate to the long planned trip down Baja. Rather, we’ve been face down in the details of scaling our 10kw and 20kw Power Pallet production, as well as sprinting towards the finish of our first 100kw shipping container based system. This of course is not a problem, and we thank all of you for making this adventure more interesting with each passing month. The challenge now is just keeping up with the growth in interest and all of your notes. We’re now 15 people full time at……

New Year Power Pallet Upgrades, GEK CHP, & Other Upgrades

Welcome to the New Year. Here’s what we’ve been up to for the last couple months, and some pointers to what’s coming in the months ahead. This winter we’ve been deep in Power Pallet refinement in response to user feedback and general product maturation. The upgrades fortunately no longer relate to the core gasifier, but rather to details in the larger Power Pallet control system and integrated product. The raw gasifier is what always gets the attention, but we’re finding that real usability is achieved (or not) across lots of details elsewhere. Once you get past the early demos and……

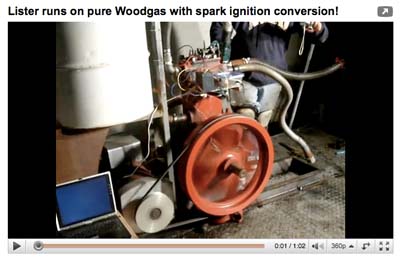

Workshop this weekend – Lister spark conversion – 6 Gas Analyzer now in house

Gasification and Biochar Workshop this coming weekend- October 8-11 Last chance reminder! The next quarterly workshop at ALL Power Labs is coming up this weekend. We hope you will join us for what is always a very enjoyable descent into (and back out of) the deep recesses of biomass thermal conversion. The workshop offers education, research reports and hands-on experience to bring more people to successful operation of small scale gasification and pyrolysis units. The event is open everyone, not just GEK or BEK users/owners. So come and join us while we progressively make small-scale gasification and pyrolysis a reasonable……

The Masonic Method: How to Operate a Downdraft Gasifier

Driving a gasifier is hard. Proper hearth dimensioning and good fuel is important, but not enough to guarantee success. Most of us learn an informed operator is also needed. In fact, an informed operator is often the most important variable on the road to success. Unfortunately, it is also the variable that varies the most. Things would be much easier if we had the equivalent of a “speedometer” and “tachometer” to guide the operator. Something like a car where we have a gauge that tells us how fast we are going, and another gauge that tells us how hard we’re……

British EE betrays Lucas heritage- Lister diesel runs on electronic spark ignition!

The workshop weekend was a rousing success- the highlight of which was likely the Ken Boak and Darryl led effort to convert a Lister diesel to spark ignition for 100% woodgas operation. This settled the long running debate as to whether a spark plug in the precombustion chamber of a Lister will actually light a wood gas fuel/air charge. The answer is yes. It also answered the related question of whether the pull rate of a standard 6/1 Lister is high enough to keep the gasifier hot and above tar making temps. The answer is also yes. This is great……

Next Workshop Weekend: Feb 19-21, 2010, Berkeley, CA.

Gasification PowerExchange Workshop #7: Next Gen GEK 10kw gasifier genset skid and BEK biochar running. Gasification Lecture and Demo: Friday, February 19, 7:30-9:30PM Building, Running and Testing: Saturday and Sunday, February 20 & 21, 11am – 7pm Location: ALL Power Labs, 1010 Murray Street. Berkeley, CA Contact: jim ^at^ allpowerlabs.com Cost: Free if you are a GEK or BEK owner, either through self build or purchase. $100 if you are not. The next of our quarterly gasifier workshop weekends is set for Februrary 19-21. The purpose of this ongoing series of workshops is to help bring more people to successful……

Tar vs Soot testing: Soluble separation method

Bear Kaufmann finished another run on the GEK test and datalogging rig and posted the results here: http://gekgasifier.pbworks.com/ Instrumented-Walnut-Shell-Run-082409. This wiki page has a large collection of graphs and other data assemblies from the run. Bear is very clever. Someday he’ll get a Phd in all this. In the interim, we get to ponder his bi-weekly posting of dissertation worthy test runs and data visualizations. Thank you Bear. The main issue he was/is trying to resolve in this test is how to measure tar. The usual “simplified tar testing method” with the greyscale seems very open to mixing the tar……