Co-composting dairy manure with SkyCarbon biochar

In the Local Carbon Network, we convert available green waste into value-added ‘climate products’ such as electricity, heat, water and biochar through a carbon negative process that combats climate change on multiple fronts.

The Local Carbon Network uses biomass gasifiers from All Power Labs in Berkeley, California, to produce SkyCarbon Biochar, a clean, porous, high-temperature char certified by the International Biochar Institute. When used as a soil amendment, SkyCarbon Biochar can offer a range of powerful agronomic benefits to plant productivity, soil biological activity, water retention, pest management and mineral uptake.

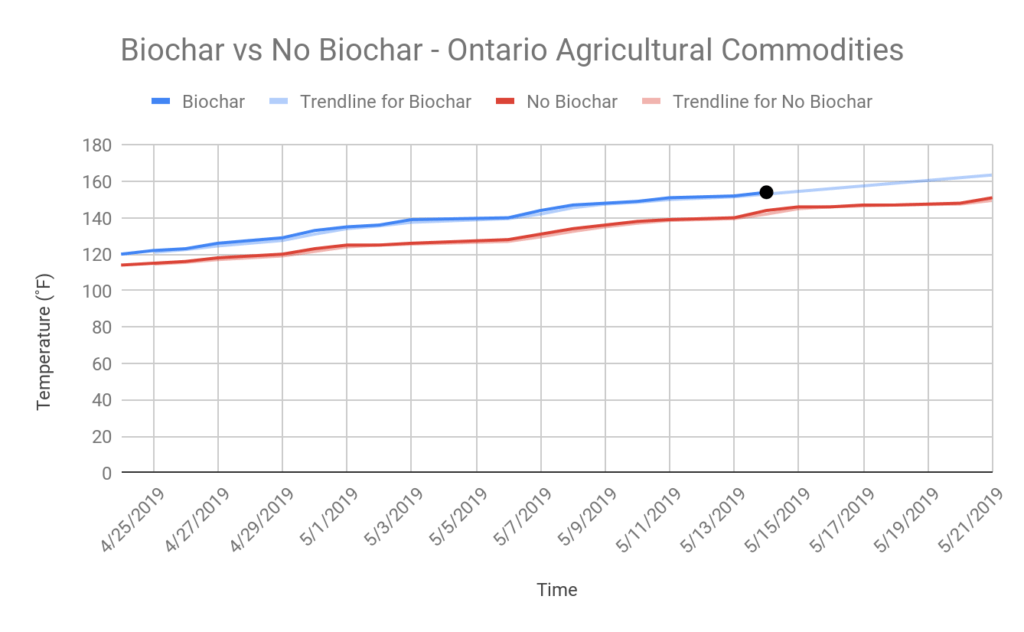

We have found that these results are best achieved through combining or ‘co-composting’ SkyCarbon Biochar with nutrient-rich organic matter at the beginning of the composting process. Through co-composting, the char is biologically ‘charged’ or ‘activated’ with microbes and nutrients that enhance its benefits. In addition, compost piles containing SkyCarbon Biochar tend to reach higher temperatures and stay hotter longer, significantly reducing the processing time and allowing compost to be harvested earlier.

Ontario Agricultural Commodities

In April of this year, the LCN began working with Ontario Agricultural Commodities (OAC), a commercial-scale composting operation in Ontario, California, to implement A/B trials with SkyCarbon Biochar in dairy manure composting. Before partnering with OAC, our experience with co-composting SkyCarbon Biochar had primarily been with green waste composting, and so we were excited to see what would happen when our char was mixed with a dairy-manure composting process.

Experimental design:

Treatment and control test with two dairy-manure compost piles, approximately 200 gallons each, started at the same time. The treatment pile was composed of 10% biochar, 90% manure, the control pile of 100% manure. Total biochar added to the treatment pile was 20 gallons of biochar at start, and 15 gallons later. Moisture was added to piles every three days. Pile temperatures were measured three times a week.

As you can see, the compost pile with biochar started hotter and stayed hotter longer than the pile without. Achieving and sustaining higher compost temperatures is particularly important for manure composting as hotter piles eliminate the threat posed by pathogens originating from animals. OAC harvests its piles 15 days after they have reached 131F, and as a result of the elevated temperatures, the SkyCarbon biochar pile was ready eight days earlier than the control pile, a 30% decrease in processing time! OAC staff also observed increased moisture content in the biochar pile, which would improve the overall effectiveness of the compost.

These are exciting results for our first foray into commercial-scale manure composting, and as we continue to combine SkyCarbon Biochar with different types of compost we look forward to testing for the additional known benefits of biochar to composting processing such as reduced GHG emissions, higher pH, enhanced organic matter, and increased nitrogen and other plant nutrients.

The LCN is actively seeking partners to demonstrate the many benefits of SkyCarbon Biochar, so if you are interested in collaborating on a solution that addresses climate change, soil degradation and world hunger, reach out!