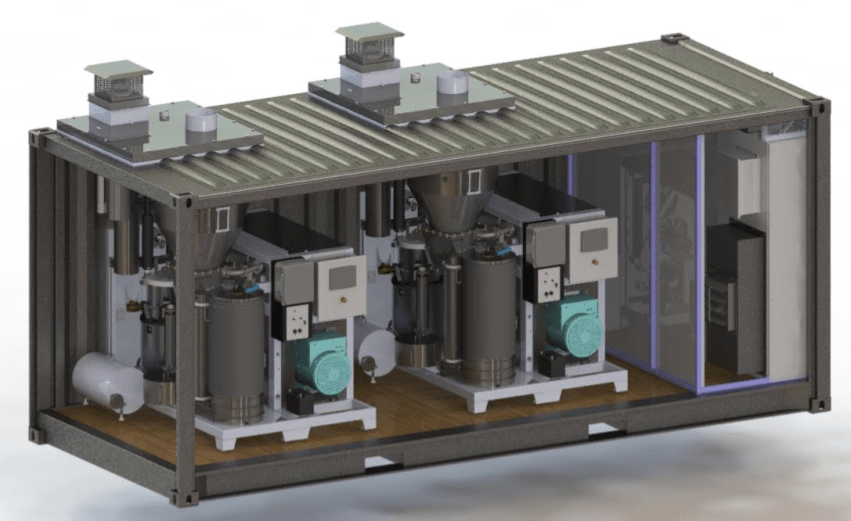

APL is developing a new integrated Carbon Conversion Hub, a comprehensive system designed for rapid, off-the-shelf, distributed-scale deployment. The system integrates our dual PP30 50kW containerized, biomass-fueled, combined heat and power genset, which can also be supplied with microgrid controls and battery storage.

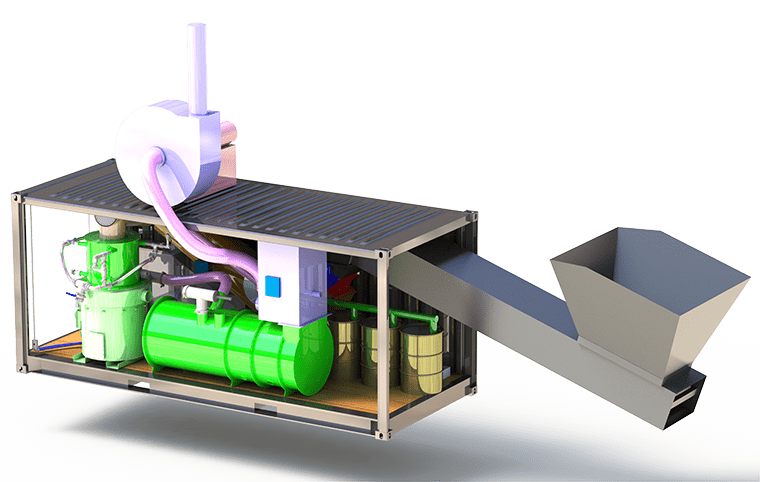

Also included with this conversion hub will be two of our new high-volume, containerized, Chartainer biomass-to-heat/biochar units, each of which can process 250 kg of biomass/hour, along with an output of 50 kg of highest quality biochar and 50 kW of thermal energy per hour.

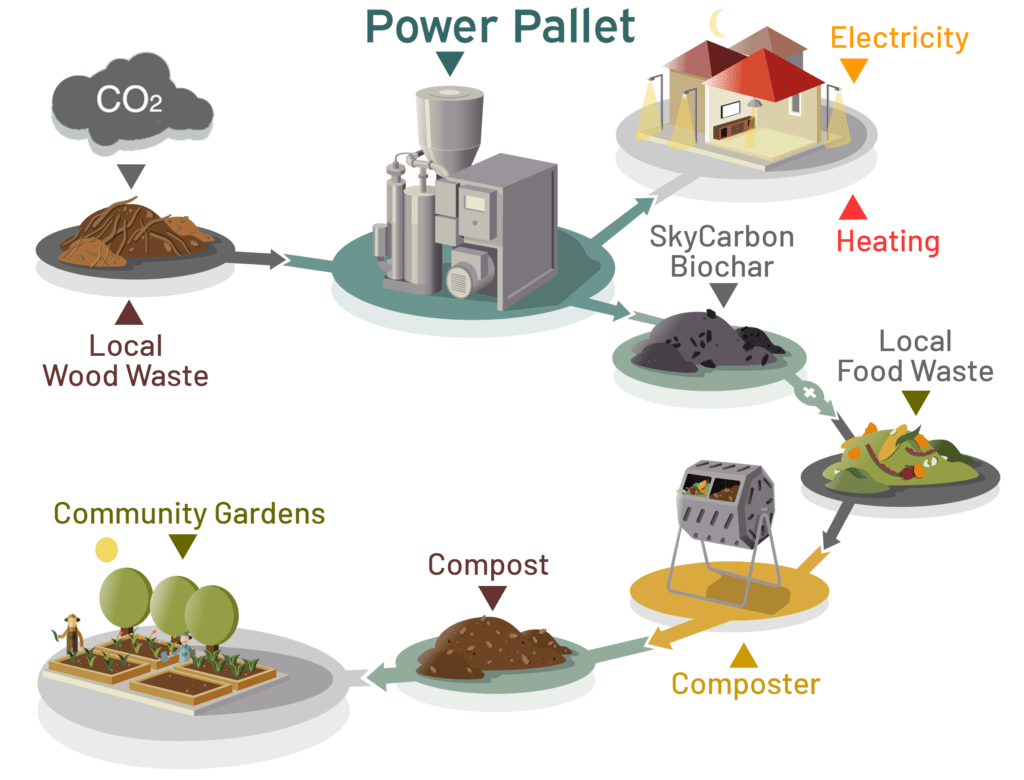

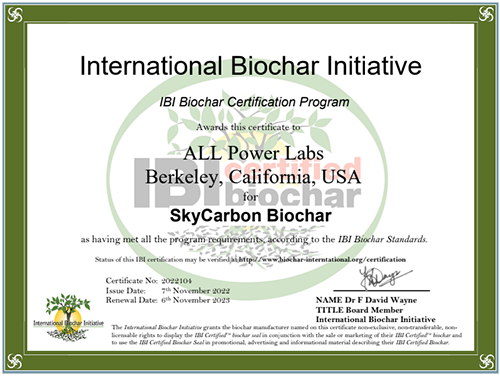

Evidence has been continuing to accumulate supporting the extensive carbon-removable potential of converting waste biomass from forestry and agricultural producers into biochar, especially when included in co-composting operations. APL has always focused on integrated high-efficiency solutions, and this system incorporates a wider range and higher throughput of multiple commodities of biochar, renewable energy, and carbon removal credits than any previous system offering.

This new high-capacity system will process over half a tonne of biomass per hour, with very significant carbon-credit potential from over 100kg of tar-free geo-conductor SkyCarbon biochar per hour. The new swirl hearth design of the Chartainer reactor also allows for a much wider range of suitable feedstock, greatly increasing viable use cases.

Each Carbon Conversion Hub includes a support and infrastructure package to facilitate partnering with our carbon-drawdown initiative, The Local Carbon Network (LCN). APL’s engineers have been working with biologists, agronomists, farmers, and climate researchers to perfect this biochar-retort technology as well as biochar application techniques and regenerative agriculture practices with the goal of maximizing carbon-drawdown impact and credits.

APL Technology’s Comprehensive Integrated Carbon Mitigation Strategy